Contemporary systems for heating, ventilation and air conditioning (HVAC) rely to a great extent on technology for flow and energy calculation. Owners of commercial and industrial facilities aim to deploy advanced flow metering solutions that allow them to accomplish optimum hydronic cooling and heating levels, even under very difficult conditions. In chilled/hot water systems, the reliability and efficiency of pumps may have a huge effect on running costs and performance.

To change the chilled/hot water flow, many construction systems now combine variable speed drives with pumps. Without losing resources or augmenting the wear on facilities, this method suits the water flow to the building’s needs.

Experience has demonstrated that to reach optimum hydronic cooling and heating inside large buildings and services, pump assets are critical to achieving the correct volume of flow at the right pressure. Usually, the flow rate of these pumps is observed by the chiller’s maximal flow rate or the maximum flow rate needed by the fan coils and air handling devices.

Building operators in charge of hydronic HVAC systems are presented with the mapping of all primary measuring points for the use of water and electricity, as well as the calculation of flow at both the specification rate and the minimum rate needed for the optimum operation of the equipment. While the use of pressure transmitters can effectively do this, the procedure is vulnerable to obstructed impulse tracks, diaphragm failures and other possible defects. Flow meter technology offers a more effective and efficient approach and helps pump performance operators to track continuing wear.

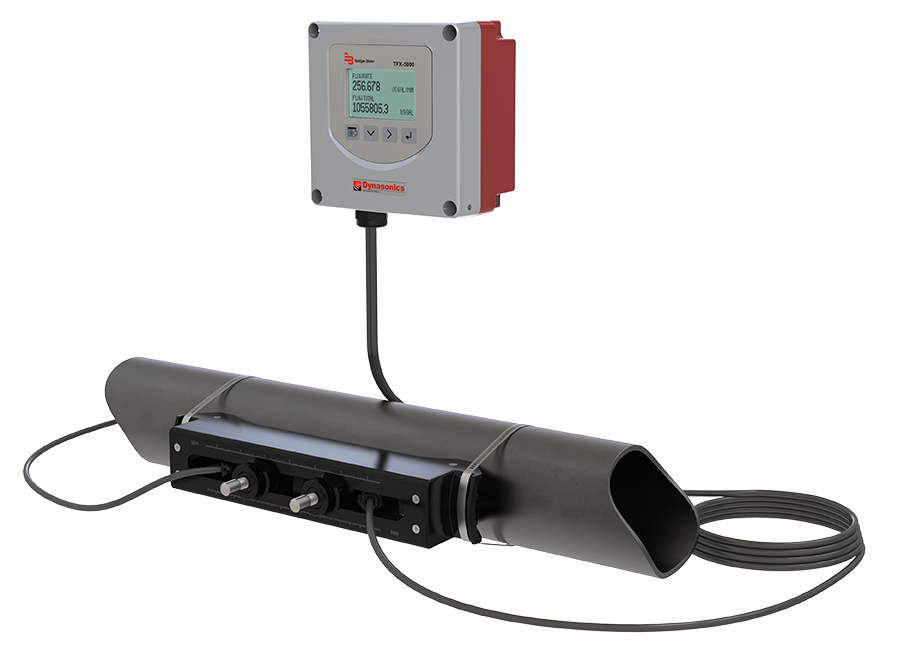

In recent years, ultrasonic transit time flow measurers have emerged as a common alternative for HVAC-related applications. Ultrasonic waves propagate upstream and downstream across the pipe wall and through the liquid circulating in the pipe with this technology. The meter measures the speed and flow rate by calculating the deviation in the travel time and understanding the pipe dimension.

Clamp-on flow meters for ultrasonic transit time can validate that water is correctly circulated through piping loops for HVAC units’ chilled and hot water sides, so that pumps can pass water via the system in a manner that guarantees higher efficiency and reduced costs of the asset life cycle.

To read more, visit http://digital.pumpsandsystems.com/publication/?m=38812&i=686605&p=38.

The Avanti Company was founded in 1977 by Paul and Justine Devlin and is headquartered in Avon Park, FL. We provide water meters, metering systems, AMI support, on-site flow meter testing, sewer flow monitoring, inspection, and assessment services for the water, wastewater, agricultural, petroleum, and industrial marketplaces. Avanti represents products from McCrometer, Itron, Hach Flow, Honeywell/Elster, 64 seconds, Infosense, Nicor, Badger Meter, Syrinix, and others. Please visit our website at www.avanticompany.com, email us at info@avanticompany.com, or call us at 863-453-5336 for assistance with all of your flow meter and metering system needs.