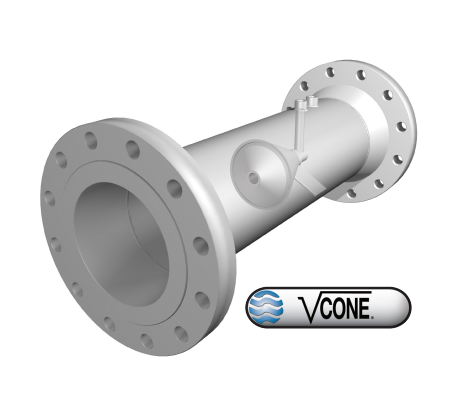

Cone meters have been around since the 1980s, putting them on the map as one of the most useful industrial meters for over 30 years. However, they often get confused with other technologies, but knowing how cone meters work can make a big difference in understanding flow meters.

McCrometer, Inc. invented and patented the first-ever cone meter, the V-Cone ® Flow Meter, in 1985. In 2022, there are over 75,000 and counting McCrometer V-Cone flow meters installed on job sites across the globe.

Cone meters are often called V-Cones as well, but V-cone is a registered trademark of McCrometer, Inc. The generic term is just “cone meter.”

A common misconception about cone meters is that many users only think they measure gas. That is not true. They can also measure steam and liquids from multiple industries. Cone meters can work well in the oil and gas industry, the chemical industry, the electric and power industry, the food and beverage industry, with HVAC systems, metals, and mining, the paper industry, and the wastewater industry.

V-Cone flow meters have been used in the world’s highest pressure systems – up to 15000 psi. They can be found in the ocean’s depths, reaching 10,000 feet of subsea levels with modules, and even on satellites in space. In fact, they are so strong and durable that they are used on United States Naval warships!

More than 1,000 V-Cone flow meters prevent dangerous conditions from gas compressors and high pressure surging flow conditions through a technology referred to as “anti-surge.”

The Avanti Company sells McCrometer’s V-Cone® along with other types of collection system meters.