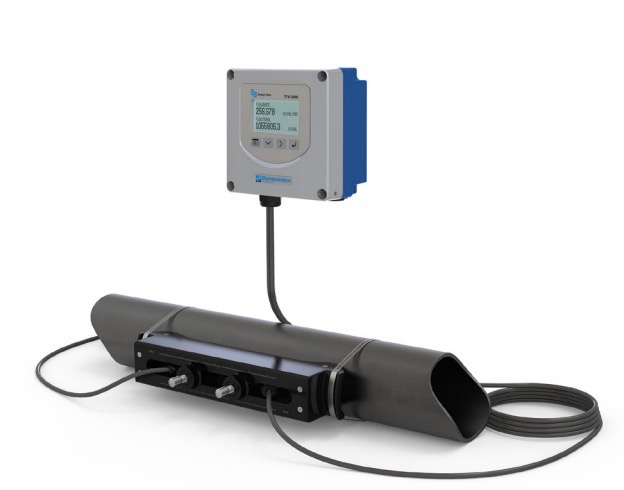

In the past, installing new meters for non-billing purposes has been an expensive and time-consuming process. There needs to be a hole that can accommodate one or more workers, or in some cases, a crane. Additionally, the system needs to be stopped and flushed. Because of this, many put off replacing or adding meters to the system unless it’s absolutely necessary. In comparison to electromagnetic meters and other metering technologies, a single person can install an ultrasonic clamp-on meter in confined spaces in about 30 minutes. By freeing up personnel to handle other crucial tasks, all of this and more can result in significant savings.

Here are three major areas where ultrasonic clamp-on meters can save you money:

Reduction of Non-Revenue Water (NRW)

When measuring water usage or flow rates, the meters can be quickly deployed in situations that are temporary, permanent, or semi-permanent. One of these situations that occurs more frequently is the search for discrepancies that could indicate leaks. They can quickly identify potential NRW and perform the necessary repairs when integrated into a SCADA or other system.

Quick and Easy Installation

In order to cut the pipe for inline meters, the system must be shut down, flushed, and saws must be brought in. Large-diameter pipes might need a crane to be raised and lowered. The entire installation process can take up to a day and is very expensive. The installation process for clamp-on ultrasonic meters is as quick and easy as it gets. Without interrupting service, the entire process can be finished by one person in as little as 30 minutes. Personnel don’t need prior knowledge or training because the device itself provides step-by-step instructions for performing the task correctly. Additionally, the installation can be done in confined spaces with less excavation, which saves time and money.

Simple to Relocate

Although ultrasonic clamp-on meters can be installed permanently if necessary, the ability to move them and reinstall them in new locations results in significant cost savings. For instance, if conducting a water age study the meters can be easily removed after collecting all the necessary data, and the procedure can then be repeated in a different sector. As a result, there is no longer a need to spend money installing numerous permanent sensors throughout the entire water distribution system.

To learn more about the Avanti Company and the services and products we provide, including flow meters and on-site flow meter testing, please visit us online or call us at 800.284.5231.